Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Model No.: 1000

Certification: ISO

Usage: Other

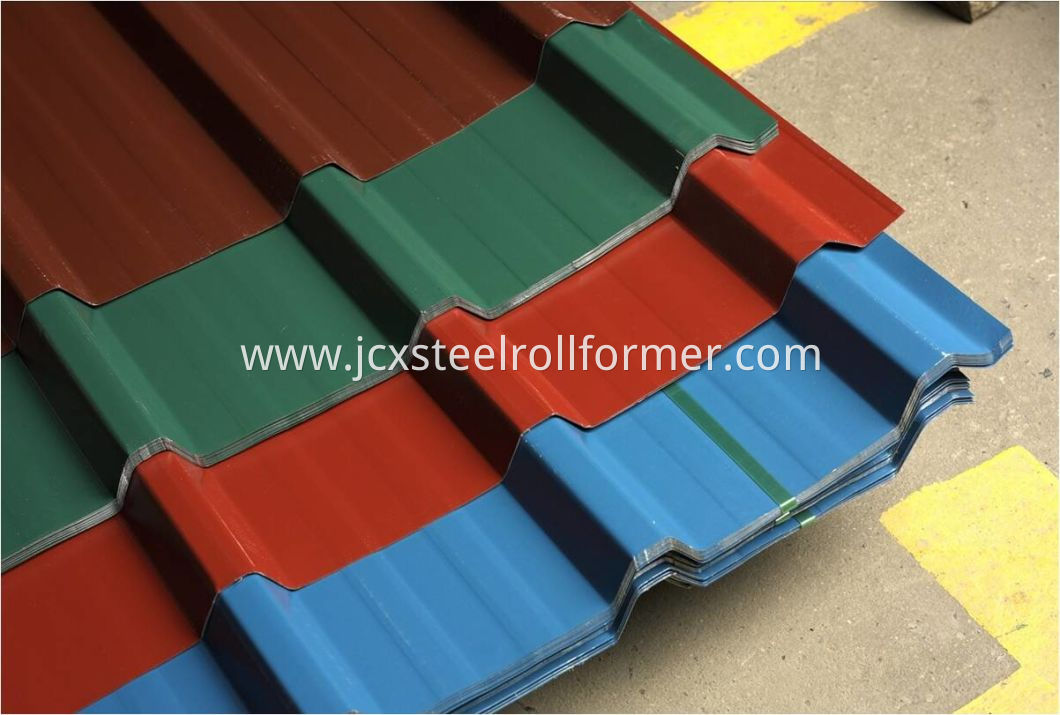

Tile Type: Colored Steel

Condition: New

Customized: Customized

Transmission Method: Electric

Packaging: covered with plastic film

Productivity: 40sets Per Month

Transportation: Ocean,Land

Place of Origin: China Hebei

Supply Ability: 40sets Per Month

Certificate: CE, ISO

HS Code: 84552210

Port: Tianjin

Payment Type: L/C,T/T,Paypal

Incoterm: FOB,CFR,CIF,FCA,CPT

galvanized roof profile forming machine is a so much necessary roll forming equipment that produces box roofing and siding panels for industrial, agricultural and individual buildings.

For our roll forming machine,it is customized design.Different designs can be cusotmized as your request.If you are interested in our machine.

the final product can be cut as per set length controller,and the length is automatically measured by encoder.When final product reached set length,machine will stop to cut the sheet automatically.Finish thhis action,the machine will run again continuously

| NO. | Description | Quantity (set) | Remark |

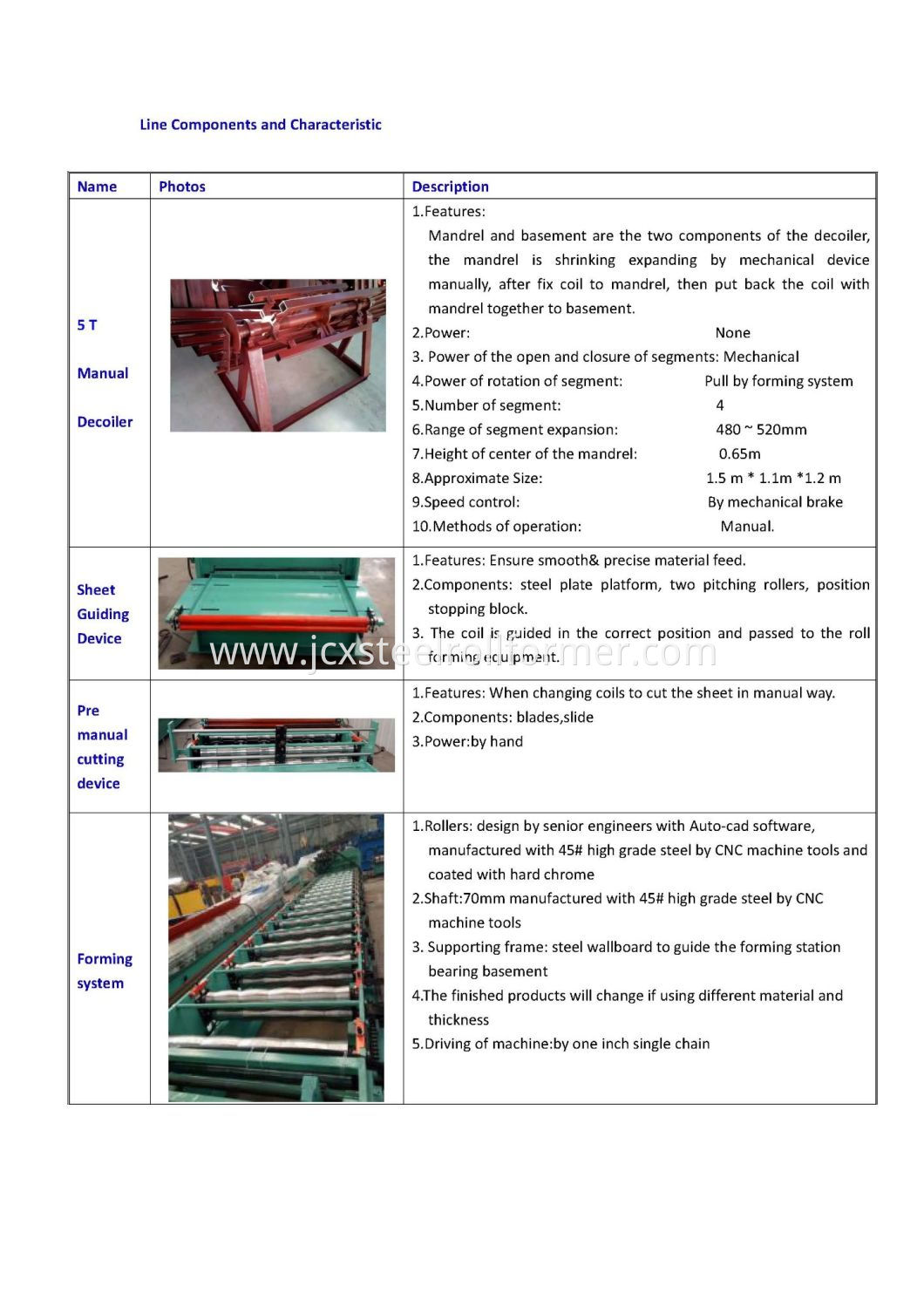

| 1 | 7T Manual decoiler | 1 | |

| 2 | Guiding device | 1 | One complete unit as main machine |

| 3 | Forming system | 1 | |

| 4 | Transmission system | 1 | |

| 5 | Hydraulic guillotine | 2 | |

| 6 | Support table | 2 | |

| 7 | Hydraulic station | 1 | |

| 8 | Control box | 1 | |

| 9 | Manual collecting table | 2 | |

| 10 | Spare parts and tools | 1 | As attaching list |

| No | Item | Parameter | Note |

| 1 | Forming Speed | Max12-15m/min | Excludes cutting |

| 2 | Forming station | 16 or 13 groups | |

| 3 | Total Power | 5.5+4kw | |

| \4 | Total Weight | About 4200KGS | |

| 5 | Voltage | 380v,50hz,3p | |

| 6 | Diameter of shaft | 70mm | |

| 7 | Installation Size | 13 * 1.1 M*1.4 | |

| 8 | Sizes of chain | Double 0.6inch chain | |

| 9 | Thickness of wall structure | 18mm |

| No | Item | Parameter | Note |

| 1 | Forming Shaft | 45# steel with grinding process | |

| 2 | Forming Roller | 45# steel with tempering heat treatment and hard chrome coating | |

| 3 | Cutting Blade | Cr12 with hard treatment | |

| 4 | Control System | DELTA PLC& transducer, low voltage:SIEMENS. | |

| 5 | Electrical motor | From jiangsu | |

| 6 | Bearing | China quality brand | |

| 7 | Chain | China quality brand | |

| 8 | Hydraulic parts | China quality brand |

Product Categories : Roof And Wall Panel Roll Forming Machine > Trapezoidal Sheet Roll Forming Machine

Home > Products > Roof And Wall Panel Roll Forming Machine > Trapezoidal Sheet Roll Forming Machine > Galvanized Profile Sheet Forming Machine

Send Inquiry

Mr. Jason Zhang

Email:

Send Inquiry Tel:86-318-8189095

Fax:86-317-8189095

Mobile Phone:+8615720371583

Email:

Address:ECONOMIC DEVELOPMENT ZONE, Cangzhou, Hebei

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.