Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Model No.: bottom shutter door

Control System: PLC

Certification: ISO

Usage: Other

Condition: New

Customized: Customized

Transmission Method: Electric

Color Of Machine: Blue Or As Your Request

Main Power Of Machine: 5.5kw

Usage Of Machine: Shutter Door Forming Machine

Material Thickness: 0.4-1mm

Voltage Of Machine: 380v,50hz

Material Of Rollers: Cr12 With Quenching Treatment

Driving Of Machine: Gear

Material Of Shaft: S45c With Qneuching Treatment

Packaging: standard overseas packing

Productivity: 40sets Per Month

Transportation: Ocean,Land

Place of Origin: China Hebei

Supply Ability: 40sets Per Month

Certificate: ISO9001

Port: Tianjin

Payment Type: L/C,T/T,D/P,Paypal,Money Gram,Western Union

Incoterm: FOB,CFR,CIF,FCA,CPT

Botton shutter door machine only make bottom of shutter door,with punching.

easy operation,Our bottom Roller Shutter Door Forming Machine is designed for bottom shutter door only.It is composed of Manual Decoiler,main forming part and automatic cutting or saw cutting.

1.Profile of shutter door design:

2.Working process of rolling up door forming machine

3.Technical details:

Capacity: 3 tons

Material: #45 steel quenched

Power:2.2KW,03 Phase, 220/380V, 50HZ/60HZ

Method of open and close of segments: manual

Number of segments:4 pieces

Range of segment expansion: ø480- ø520

Inner diameter of coil: ø508

Maximum outer diameter of coil: ø1,300

Feeding speed:25m/min(transducer control)

Stations: 24

Rollers material: CR 15, HRC 60. Chrome coated: 0.03-0.05mm, Strength (MPA): 70 tons, 800 MPA

Shaft: diameter 55mm, material is #45 steel. Quenched hot treatment. Strength of the main shaft (MPA): 70 tons, 650MPA

Bearing brand: FAG Germany

Main motor: 11KW, 380/220V, 50/60HZ, 3 Phases (Siemens Brand),Two motors

Transmission by gear

Station material: cast steel

Machine is equipped with cooling system

Touch screen brand: Delta

PLC brand: Siemens

Inverter brand: Siemens

Main components for low pressure electricity: Schneider Germany

Encoder: Omron

Sensor: Balluff B+F brand

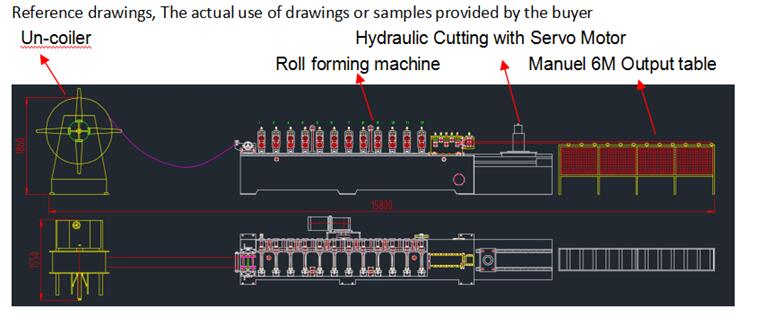

Control motion/production process: Un-Coiler---12 stations roll forming machine---Hydraulic cutting by servo---output table

Cutting type: hydraulic cutting with servo motor

The material of knives: CR12MOV; heat treatment HRC 55-60, Quenched; the Strength in MPA: 950

Servo motor: 1.5KW, 220V

Tolerance of length: ±0.5mm

Action: the host does not stop, servo track to cut off

Hydraulic Motor: 5.5KW, 220V/380V, 50HZ/60HZ, 3 Phases, Siemens brand

Hydraulic pump: Yuken brand Taiwan

Hydraulic valve: Rexroth Germany

Hydraulic cylinder: China

The Hydraulic station have Accumulator

The stations have 1 valves

Length: 6 meters

Drive type: rollers

Material: galvanized sheet

Galvanized steel: 1.0-1.3mm

Roll forming machine space: 8.7m*1.55m*1.36m

Working space:18m*3m*3m

15-18m/min (including cutting)

Bearing in main shaft: 20 pcs

Other bearing (sub-rollers): a few

Limit switch:2 pcs

Low pressure electricity: a few

Relay:10 pcs

Oil tube: 2 pcs for each tool

Connector: a few

Cutting knives: 2 extra

Upper shaft and down shaft: 2 pieces

Station: 1 pieces

Gear: 2 pieces

Product Categories : Roller Shutter Door Roll Forming Machine > Bottom Shutters Profile Forming Machine

Home > Products > Roller Shutter Door Roll Forming Machine > Bottom Shutters Profile Forming Machine > Shutter door machine for Bottom

Send Inquiry

Mr. Jason Zhang

Email:

Send Inquiry Tel:86-318-8189095

Fax:86-317-8189095

Mobile Phone:+8615720371583

Email:

Address:ECONOMIC DEVELOPMENT ZONE, Cangzhou, Hebei

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.