Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

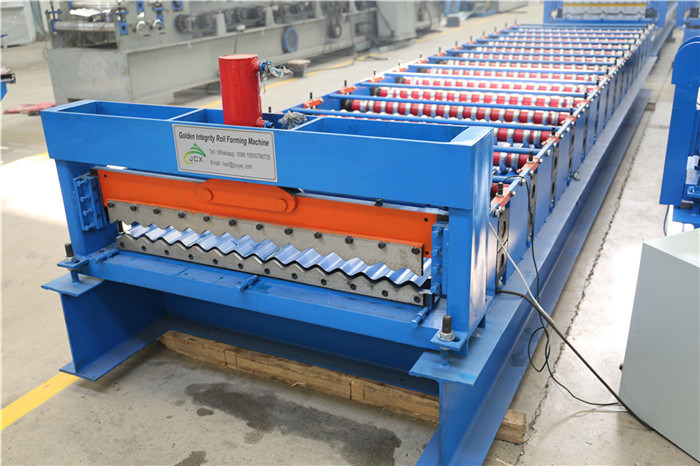

Model No.: Corrugation Galvanized Roof Steel Forming Machine

Brand: JCX

Certification: Other

Usage: Metal Roofing And Wall Sheet Machinery

Tile Type: Glazed Steel

Condition: New

Customized: Customized

Transmission Method: Hydraulic Pressure

Structure Of Machine: 350H Beam

Forming Stations: 14-18

Voltage: 380V 50Hz 3phase, Or As Your Request

Pressing Thickness: 0.3-0.8mm

RAW MATERIAL: PPGI, GI, Aluminum

Trademark: JCX, OEM, ODM

Power(KW): 5.5+4kw

Name: Corrugation Galvanized Roof Steel Forming Machine

Control System: By PLC And Inverter

Packaging: the whole Wiped Anti Rust Oil, PLC controller covered by foam film; Spare parts and some small parts packed in plastic tooling box;

Productivity: 60sets

Transportation: Ocean,Land

Place of Origin: Hebei, China

Supply Ability: 60sets

Certificate: CE, ISO, ISO9001: 2008

HS Code: 8455221000

Port: Tianjin, China

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF

Corrugation Steel Forming Machine-galvanized roof machine

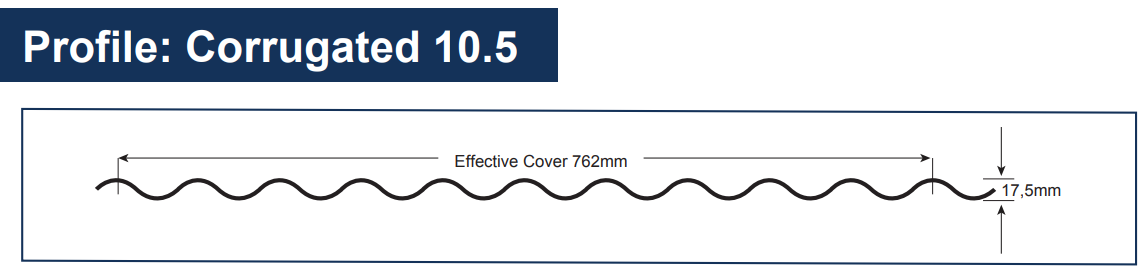

1. Profile drawing:

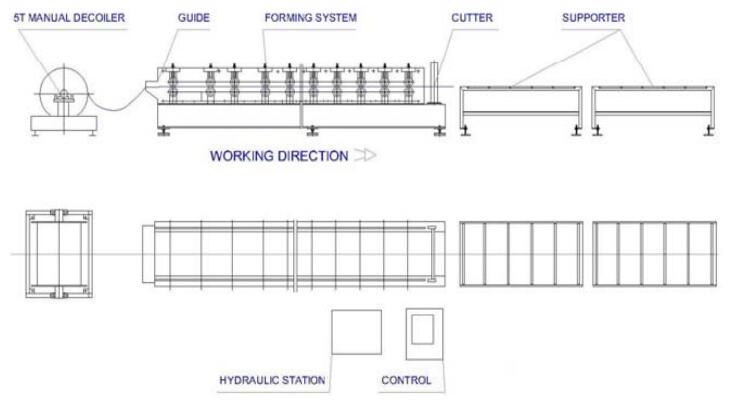

| Suitable to process | Steel plate |

| Width of the plate | 1000mm/1200mm/1250mm |

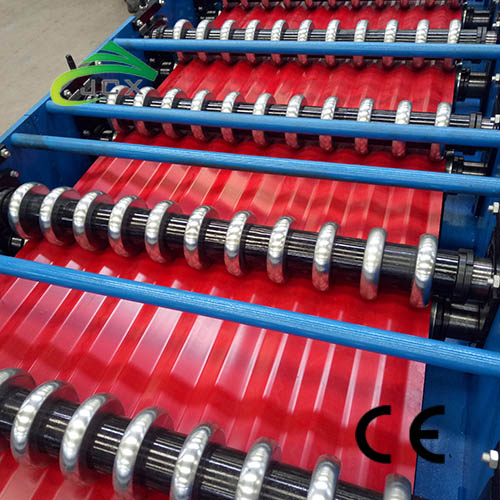

| Rollers | 15rows |

| Dimensions | 8.8*1.55*1.51m |

| Power | 4kw+4kw |

| Thickness of the plate | 0.3-0.7mm |

| Productivity | 8-15m/min |

| Diameter of the roller | ¢75mm |

| Weight | About 3.4T |

| Voltage | 380V 50Hz 3pha |

9. More Machine Details:

9. Finished Panels:

Product Categories : Roof And Wall Panel Roll Forming Machine > Corrugated Roof Roll Forming Machine

Home > Products > Roof And Wall Panel Roll Forming Machine > Corrugated Roof Roll Forming Machine > Corrugation Galvanized Roof Steel Forming Machine

Send Inquiry

Mr. Jason Zhang

Email:

Send Inquiry Tel:86-318-8189095

Fax:86-317-8189095

Mobile Phone:+8615720371583

Email:

Address:ECONOMIC DEVELOPMENT ZONE, Cangzhou, Hebei

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.