Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Model No.: Fully-automatic C Z Section Purlin Roll Forming Machine

Brand: JCX

Forming Stations: 16

Voltage: 380V 50HZ

Certification: Other

Warranty: 1 Year

Customized: Customized

Condition: New

Control Type: CNC

Automatic Grade: Automatic

Material: Steel Strip

Origin: China Hebei

Model No.: C Scetion Forming Machine

Thickness: 1mm-3mm

Width Of C Section: 80mm-300mm

Chains: 1.5inch

Control System: PLC: Panasonic, And Touch Screen

Inveter: Sheneder

Packaging: One 40GP Container, Covered with Plastic Films

Productivity: 40sets Per Month

Transportation: Ocean,Land

Place of Origin: China Hebei

Supply Ability: 40sets Per Month

Certificate: CE, ISO9001

HS Code: 8455221000

Port: Tianjin, China

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF

C section forming machine is machine that produces C shaped steel channels continuously out of galvanized or cold rolled steel strips from feeding, punching for holes, bending and cutting.

Now c section are widely used for steel constructure.Workshop,warehouse,commercial building.This machine can make c purlin sizes from 80-300,by aumatic changing sizes.no need extra labor.

Compared to traditional purlins, steel purlins have so many advantages, they are light, easy to install, and recyclable for other buildings etc. Therefore, as we can see, in mordern steel industrial buildings or prefab enineered buildings, people always use C purlins, Z purlins and sometime U purlins without flange stiffeners as well.

C steel purlin roll forming machine with hydraulic cutter and post punching tools

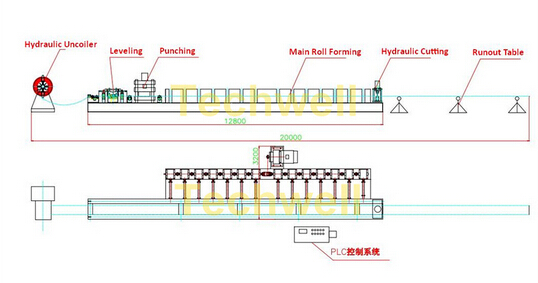

Working Flow & Layout:

Certfications:

Product Categories : C/Z Purlin Roll Forming Machine > CZ Purlin Roll Forming Machine

Home > Products > C/Z Purlin Roll Forming Machine > CZ Purlin Roll Forming Machine > Fully-automatic C Z Section Purlin Roll Forming Machine

Send Inquiry

Mr. Jason Zhang

Email:

Send Inquiry Tel:86-318-8189095

Fax:86-317-8189095

Mobile Phone:+8615720371583

Email:

Address:ECONOMIC DEVELOPMENT ZONE, Cangzhou, Hebei

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.