Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

2018-07-19

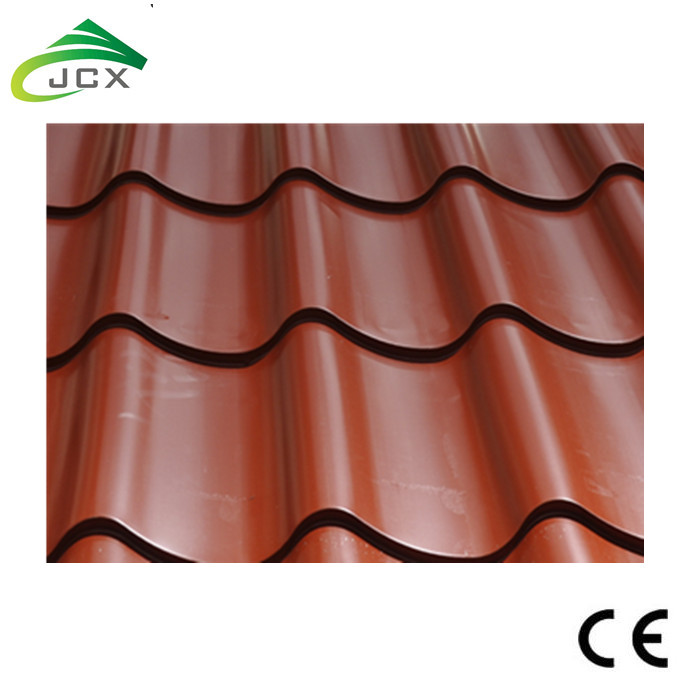

The 1100 roof tile roll foorming machine is very popular in Euro.

Specification of 1100 Roof Tile Roll Forming Machine

MACHINE SPECIFICATION

1. SPECIFICATION

§ SUITABLE MATERIALS: PPGI, GI, CR coils etc.

§ MATERIAL THICKNESS: 0.4-0.80 mm

§ Material hardness:235mpa

§ FORMING PROFILES: 1100 tiles

§ MACHINE SPEED: Around 2-4 meters/minute without cutting

§ POWER SUPPLY: 380v/50hz/3p

§ INSTALATION SIZE: 15,00 x 1,54 x 1,40 meters

§ TOTAL GROSS WEIGHT: Around 7200 kgs

§ MACHINE COLOR: Blue RAL 5015 and Yellow RAL 1018

3. DECOILER DETAILS

§ TYPE: Manual operating decoiler

§ LOADING CAPACITY: 5000 kgs

§ COIL INNER DIAMETER: Ø60-520 mm

§ COIL OUTER DIAMETER: Max. Ø1400 mm

4. GUIDING DEVICE

§ FEATURES: Ensure smooth & precise material feeding

§ COMPONENTS: Steel plate platform, two pitching rollers, position stopping block

§ FUNCTION: Material is guided in the correct position and passed to the roll forming equipement

5. MANUAL PRE-CUTTING DEVICE

§ FEATURES: Enables cutting of material in manual way

§ COMPONENTS: Blades, slider

§ POWER: By hand

FORMING SYSTEM DETAILS

§ NUMBER OF FORMING STANDS: 16 stands

§ MATERIAL WIDTH: 1250 mm

§ ROLLERS MATERIAL: High grade #45 steel, CNC machining, polishing, quenching HRC58-62 and chrome plating

§ SHAFT DIAMETER: 75 mm

§ SHAFT MATERIAL: High grade #45 steel, heat treatment

§ SIDE PLATE THICKNESS: 18 mm

§ MACHINE BASE: 36# channel steel welded structure

§ MOTOR POWER: 7,50 KW

TRANSMISSION: Chain transmission

§ CHAIN MATERIAL: 45# steel, heat treatment, HRC45-50

7. HYDRAULIC CUTTER DETAILS

§ HYDRAULIC PUMP POWER: 4 KW

§ HYDRAULIC PRESSURE: 12 Mpa

§ CUTTING BLADE MATERIAL: Cr12, quenching HRC58-62

§ CUTTING LENGHT TOLLERANCE: +/-2,00 mm

§ LENGHT CONTROLLER: Encoder and PLC system, computer counter

RUNNING OUT TABLE DETAILS

§ FEATURES: Enables running out of finished products

§ MATERIAL: Steel frame and nylon shaft

§ TABLE LENGHT: 3 m

9. HYDRAULIC SYSTEM DETAILS

§ FEATURES: Supplies initial power to the cutter throught a closed oil tank. Without cutting it is off.

§ HYDRAULIC MOTOR POWER: 4 KW

10. PLC CONTROL SYSTEM

§ OPERATION: Touch screen operation, digital display

§ FUNCTION: Enables running of all function of the machine

§ REMOTE CONTROL: PLC is equipped with remote control for running of machine forward and backward

§ VOLTAGE: 380V, 3 phase, 50 Hz

§ TRANSLATION: Software is completely translated to local language of the Buyer

§ SPECIAL FUNCTIONS: Stop to cut function to enable pre-cutting of material when order can be finished with material which is in machine.

§ SPEED ADJUSTER: PLC is equiped with frequency converter which enables speed adjusting

Share to:

Send Inquiry

Mr. Jason Zhang

Email:

Send Inquiry Tel:86-318-8189095

Fax:86-317-8189095

Mobile Phone:+8615720371583

Email:

Address:ECONOMIC DEVELOPMENT ZONE, Cangzhou, Hebei

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.