Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

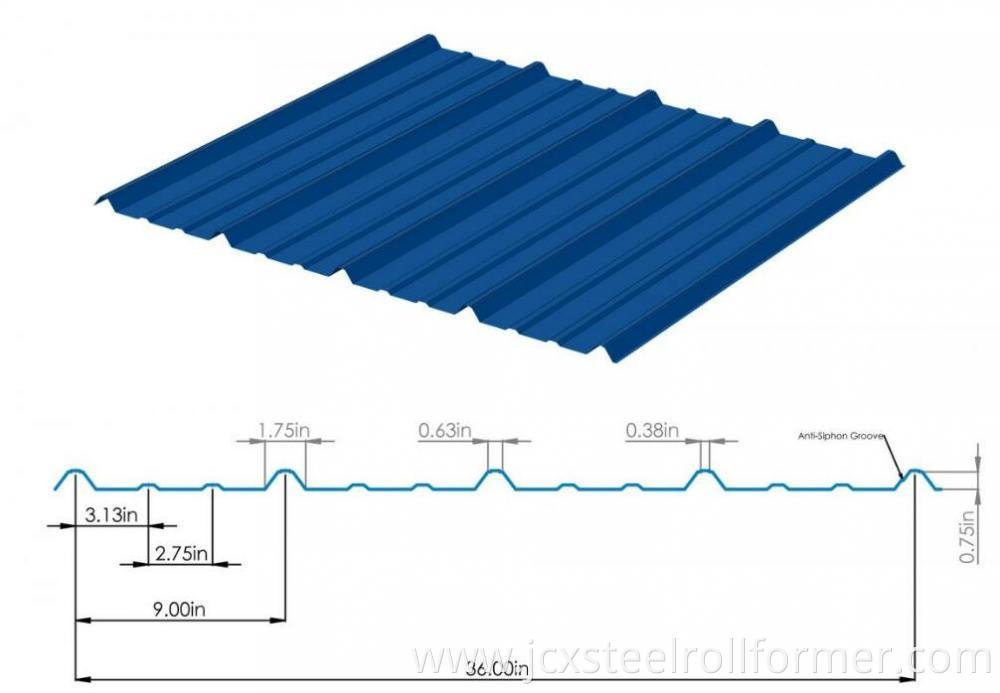

Model No.: ag panel

Productivity: 25sets/Month

Place of Origin: China

Supply Ability: 25sets/Month

Payment Type: L/C

Roll former for ag panels

For our roll forming machine,it is customized design.Different designs can be cusotmized as your request.If you are interested in our machine. We would ask you some questions first. 1) Do you have an idea design you need?Including measurement.If pls tell me where are you from.So we can send you some popular designs at your place. 2) What is material thickness u use?Max and Min? 3) What is hardness of material?Is it standard?Or full hard? 4) What is voltage of machine u need?380V,50HZ?220V,60HZ?OR 415v,50HZ?We can make is as your request. If you have some questions about our machine just let us know.

First of lall,let us know some thing about AG panel.What is AG panell?AG Panel is a weather-resistant roofing solution for resisdential house. The AG panels not only provide excellent protection against the elements and increase the life cycle of your roof but they lower the need for maintenance on your roof.

Roll forming has many cost advantages over brake forming and preformed panels. If you are not familiar with what roll forming can do for your bottom line, here are just a few of the savings you can expect...

No Expensive Shipping and Crating of Long Panels

(Have coils delivered right to your shop or jobsite)

No Panel Shipping Damage and Extensive Delays

(Just try to order one replacement panel from the factory)

Less Labor and Waste

(Run your panels to the exact length without time and material waste)

Work On Your Own Schedule - Not The Factory's

(When roof is ready -- just run your panels

Form Perfect Panels To Any Length

(Form long panels at the site or on the roof without crating problems)

| Material | Thickness | I.D | Yield Strength |

| Q235 gi&ppgi& galvalume | 0.25-0.7mm | 508mm | <=235mpa |

Shaft:Diameter of max shaft: ø70mm(hardening and tempering)

Transmission type:by one inch chain

Qty: 1Product Categories : Roof And Wall Panel Roll Forming Machine > Trapezoidal Sheet Roll Forming Machine

Home > Products > Roof And Wall Panel Roll Forming Machine > Trapezoidal Sheet Roll Forming Machine > Roll former for ag panels

Send Inquiry

Mr. Jason Zhang

Email:

Send Inquiry Tel:86-318-8189095

Fax:86-317-8189095

Mobile Phone:+8615720371583

Email:

Address:ECONOMIC DEVELOPMENT ZONE, Cangzhou, Hebei

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.