Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Home > Products > Roof And Wall Panel Roll Forming Machine > Trapezoidal Sheet Roll Forming Machine

PRODUCT CATEGORIES

View:

Supply Ability: 25sets/Month

Min. Order: 1 Bag/Bags

Model No.: ag panel

Place of Origin: China

Productivity: 25sets/Month

Roll former for ag panels For our roll forming machine,it is customized design.Different designs can be cusotmized as your request.If you are interested in our machine. We would ask you some questions first. 1) Do you have an idea design you need?Including measurement.If pls tell me where are you from.So we can send...

Supply Ability: 25sets/Month

Min. Order: 1 Bag/Bags

Model No.: pbr panel

Place of Origin: China

Productivity: 25sets/Month

Used pbr panel roll former Maybe you are confused that if PBR panel and R panel are same.The answer is NO.The photo of panel underneath fyi.Our pbr panel can produce these two PBR panel and R panel are used a lot on resisdential house.PBR is short for "PURLIN BEARING RIB" 1.Main parameters of PBR panel roll former...

Supply Ability: 40sets Per Month

Min. Order: 1 Bag/Bags

Certificate: CE, ISO

Model No.: roll forming equipment

Place of Origin: China Hebei

Metal Roofing Roll Forming Equipment our cold roll forming equipment has many cost advantages over brake forming and preformed panels. If you are not familiar with what roll forming can do for your bottom line, here are just a few of the savings you can expect... · No Expensive Shipping and Crating of Long Panels...

Brand: jcx OR odm

Packaging: standard packing,main roll forming machine are covered with plastic fiml

Supply Ability: 40sets Per Month

Min. Order: 1 Set/Sets

Certificate: CE, ISO

Galvanized roof panel machine Our roll forming equipment is always first choice to make roof,now people use metal roof a lot to replace concerate roof. This kind of roof have many advantages:easy installation,more beautuful,light weight etc. Roll forming machines have so many advantages over bending machine and...

China Trapezoidal Sheet Roll Forming Machine Suppliers

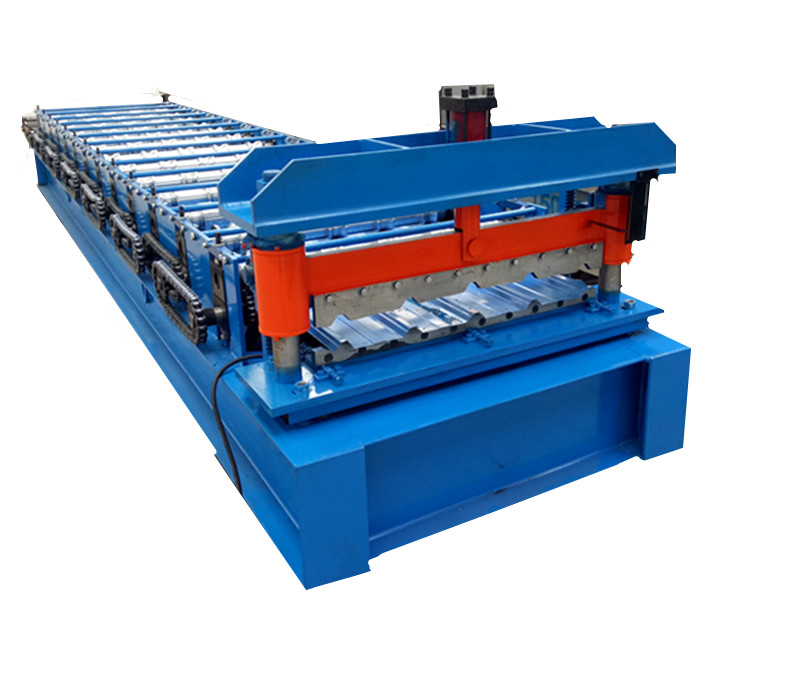

A Trapezoidal Sheet Roll Forming Machine is a regular metal sheet roll former that produces metal roofing sheets or roof panels for both individual and industrial building.

Trapezoidal roofing sheets are the most popular metal roof panels not only for residential buildings but also for commercial or industrial buildings. There are so many different profiles for a variety of applications. People like to use low-profile trapezoidal sheets for elevation and IDT roofing, while for wide-span roofing and load-bearing structures, they tend to select high-profile trapezoidal sheets. In addition, trapezoidal sheets have other names in Africa as industrial trough IT4, IT5, IT6 roof profiles, therefore people can barely find two exactly the same trapezoidal sheet roll forming machine in the markets.

TR750 Trapezoidal Sheet Roll Forming Machine

TR750 Trapezoidal Sheet Roll Forming Machine This trapezoidal sheet roll forming machine produces trapezoidal sheets from colour ppgi, gi, aluzinc sheets, and sometimes aluminium steel coils (aluminum roof panels are prefered in Nigeria). Generally, material thickness varies from 0.3 to 0.8mm, and width varies from 914mm to 1250mm. However, in some applications, material thickness can reach up to 1.5mm, like roof deck. Furthermore, in some countries or areas, people use G550 material to make full hard metal roofing sheets.

Sometimes when a client needs to produce trapezoidal sheets with different effective widths with anything else remained the same. In this case, the investment shall be made on only one machine, because a trapezoidal Roof Panel Roll Forming Machine is always adjustable for different feeding widths. This means you can make trapezoidal roof panels with different effective widths from different-width materials. However, a client must need two trapezoidal sheet roll forming machines for manufacturing two panels at the same time.

Just like the regular roof sheet roll former, a trapezoidal sheet roll forming machine typically consists the components as following:

There are different names for trapezoidal sheet roll forming machines in some regions or areas! For example, in Africa, people like to metra roll forming machine, and sometime they give the name industrial trough IT4, IT5, IT6 roof sheet roll forming machineetc.

MAXON designs and builds customized trapezoidal sheet roll forming machines. For instance, some customers ask for G550 metal roofing sheet roll forming machine, some customers may prefer a separate forming stands structure trapezoidal sheet roll forming machine, or some customers may need safety guard on the roll forming machine body etc.

Hot Products

Home > Products > Roof And Wall Panel Roll Forming Machine > Trapezoidal Sheet Roll Forming Machine

Send Inquiry

Mr. Jason Zhang

Email:

Send Inquiry Tel:86-318-8189095

Fax:86-317-8189095

Mobile Phone:+8615720371583

Email:

Address:ECONOMIC DEVELOPMENT ZONE, Cangzhou, Hebei

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.