Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Model No.: 1000-200-25

Brand: jcx OR odm

Diameter Of Shaft: 75mm

Certification: ISO

Usage: Wall

Tile Type: Colored Steel

Condition: New

Customized: Customized

Transmission Method: Electric

Material To Roll Forming: Ppgi,gi,aluminum,alu-zinc

Thickness Of Material: 0.25-0.8mm,or As Your Request

Width Of Material: 1000/914/1200/219/1250mm,depend On Final Design

Driving Of Roll Forming Machine: By Chain Driving

Structure Of Roll Forming Machine: 350I Beam

Color Of Machine: Blue Or As Your Request

Main Power Of Machine: 5.5/7.5kw

Sinzes Of Chain: Double 0.6inch Chain

Packaging: standard packing,main roll forming machine are covered with plastic fiml

Productivity: 40sets Per Month

Transportation: Ocean,Land,Air

Place of Origin: China Hebei

Supply Ability: 40sets Per Month

Certificate: CE, ISO

HS Code: 8455221000

Port: TIANJIN

Payment Type: L/C,T/T,D/P,Paypal,Money Gram,Western Union

Incoterm: FOB,CFR,CIF,CPT

Galvanized roof panel machine

Our roll forming equipment is always first choice to make roof,now people use metal roof a lot to replace concerate roof.

This kind of roof have many advantages:easy installation,more beautuful,light weight etc.

Roll forming machines have so many advantages over Bending Machine and shearing machines! It is automatic machine,saves more labor.With HMI ,you can input the orders directly,machine will work in auto,after orders are done.Machine will stop.

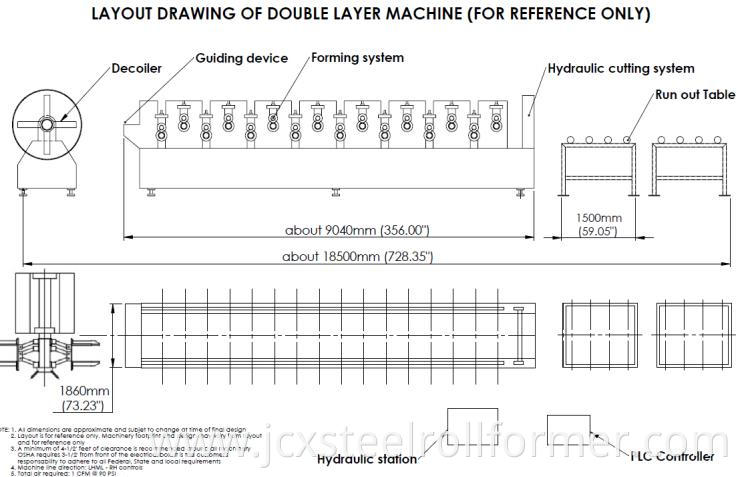

Work Flow of machine:

1000 TYPE IBR SHEET ROLL FORMING MACHINE

· Material width: 1200mm

· The effective width:1000mm

· The thickness of Coil: 0.3-0.8mm

· The overall dimensions: 8600mmX1500mmX1300mm

· Total weight: Appro.6.2 T

· Main Power: 5.5 KW

In addition, the main parts of the ibr roof panel roll forming machine are as following:

· Manual Uncoiler;

· Feeding Guider;

· Roll forming machine;

· Hydraulic Cutting system;

· PLC Control System;

· Runout Table

· Uncoiler: Manual Uncoiler

· Inner diameter: 508mm

· Outer diameter: 1250mm.

· Loading weight: 5TONs

· Forming speed: 8-12m/min.

· Forming steps: 16 stations

· Material of Shafts: 45# high-quality steel

· Diameter of Shafts: 70mm

· Material of Roller: high quality 45#steel coated with hard chrome 0.05mm.

· Thickness of Siding Plate: 18mm

· Transmission: chains-sprockets

· Motor Power:5.5 KW

· Material of cutting blade: Cr12 with quenched treatment 60-62

· Hydraulic Power: 4 KW

· This machine will automatically measure and cut the length and quantity as per clients set on the PLC touch screen.

· Panasonic PLC Control system,touch screen, frequency converter

· Voltage 380V/50HZ/3phase

Application of roof sheet:

Product Categories : Roof And Wall Panel Roll Forming Machine > Trapezoidal Sheet Roll Forming Machine

Home > Products > Roof And Wall Panel Roll Forming Machine > Trapezoidal Sheet Roll Forming Machine > Galvanized roof panel machine

Send Inquiry

Mr. Jason Zhang

Email:

Send Inquiry Tel:86-318-8189095

Fax:86-317-8189095

Mobile Phone:+8615720371583

Email:

Address:ECONOMIC DEVELOPMENT ZONE, Cangzhou, Hebei

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.