Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Model No.: corner bead

Brand: jcx

Diameter Of Shaft: 40mm

Thickness: 0.3-0.5mm

Material Of Rollers: Cr12

Color Of Machine: Blue Or As Your Request

Driving Of Machine: By Gear

Voltage Of Machine: 380v,50hz Or As Your Request

Material: Galvanized Steel Strip Or Stainless Steel

Main Power Of Machine: 3kw

Power Of Pump: 4kw

Packaging: machine is covered with plastic films

Productivity: 20/Month

Transportation: Ocean,Land

Place of Origin: Hebei Cangzhou

Supply Ability: 20/Month

Certificate: ISO / CE

HS Code: 84552210

Port: Tianjin

Payment Type: L/C,T/T,D/P,Paypal,Money Gram,Western Union

Incoterm: FOB,CFR,CIF

Corner bead angle machine dry wall roll former

We supply different kinds of roll forming machine:

Roof Panel Roll Forming Machine Cz Purlin Roll Forming Machine High Way Crash Barrier Roll Forming Machine Roller Shutter Door Forming Machine Double Layer Roll Forming Machine

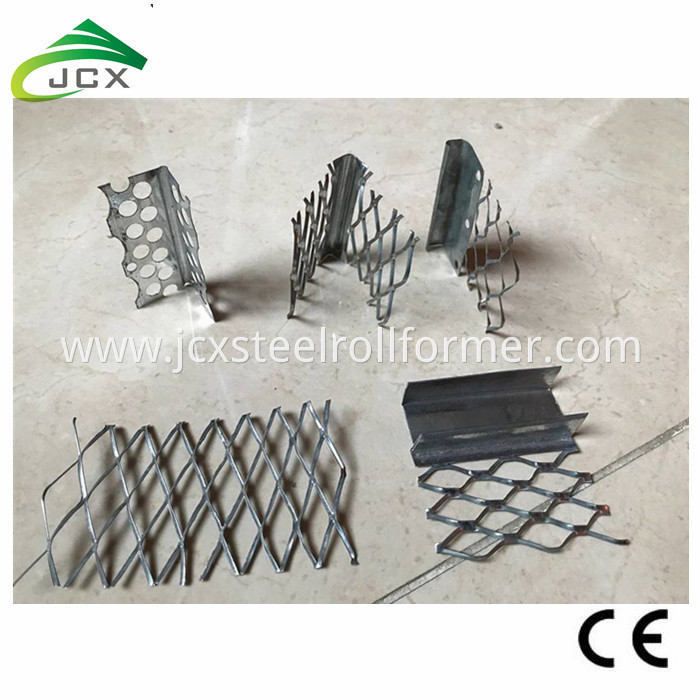

Mesh angle bead is also called corner beads.It is formed from zinc coated steel strip or stainless steel.It is used on the corner of walls,and inside of plaster,on the corner which enables the straightness ,rigidity and long life time for walls.

Our Galvanized Drywall Angle Beads Profile Machine is a complete line which can make the mesh corner bead automatically.It designed for production angle beads with mesh punching.The final product can be cut as per set length controller,and the length is automatically measured by encoder.When final product reached set length,machine will stop to cut the sheet automatically.Finish thhis action,the machine will run again continuously.It is composed of electric decoiler, punching machine,mesh punching dies,main forming,automatic cutting.

1.Component of angle bead forming machine

1) Manual Decoiler set 1

2) Main forming machine set 1

3) PLC control system set 1

4) Hydraulic pump station set 1

5) Post cut set 1

6) Electric motor set 1

7) Output table set 1

8)Punching system 1

2.ANGLE BEAD MACHINE/CORNER BEAD MACHINE TECHNICAL PARAMETER

1) Length of the main part 3000*800*1400mm

2) Weight of main part About 3 t

3) Voltage 380V/50HZ3Phase (as customer`s request)

4) Roller fixer Guide column

5) Frame Middle plate welded, Memorial arch frame type

6 Frame thickness 25mm

7 Drive mode Gear or chain

8) Material of rollers 45# steel with tempering

9) Material of shafts 45# steel with tempering

10) Diameter of shafts φ40mm

11) Number of rollers 10 rollers

12) Main power 3kw (Cycloidal planetary gear speed reducer)

Product Categories : Light Gauge Steel Framing Forming Machine > Wall Angle Roll Forming Machine

Home > Products > Light Gauge Steel Framing Forming Machine > Wall Angle Roll Forming Machine > Corner bead angle machine dry wall roll former

Send Inquiry

Mr. Jason Zhang

Email:

Send Inquiry Tel:86-318-8189095

Fax:86-317-8189095

Mobile Phone:+8615720371583

Email:

Address:ECONOMIC DEVELOPMENT ZONE, Cangzhou, Hebei

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.